Last week I asked for reader input concerning a nickel-boron-coated bolt carrier group as a way to solve various AR15 problems. Thanks to everyone who responded: your feedback has been very useful in resolving the issues I raised.

I’m implementing with my disabled shooter ‘clients’ the following ‘fixes’ recommended by readers:

- Getting those involved to shoot their AR’s with very ‘wet’ bolt carrier groups (BCG’s) and upper receivers. The heavily lubricated AR’s do appear to minimize many problems. I have serious reservations about using a lot of lube in dusty or sandy environments, based on my experiences in Africa; and it seems my hesitation is shared by some of my friends who’ve been in the sandbox in more recent years. I also question whether one can store a weapon in a sufficiently ‘wet’ condition that it’ll be usable in an emergency – won’t the excess lubrication dry on the internal parts and gum up the action, or leak out of the receiver if the weapon’s stored in an upright position, or perhaps affect the ammunition? I’d appreciate further input from readers about those points. However, as a way to ‘break in’ the AR’s to the point that they’ll run more reliably without excessive lubrication, it seems like a good start. We’ll see how it goes.

- I’ve checked several of the ‘problem’ upper receivers for issues as per reader suggestions. Two cheap uppers do, indeed, show signs of dents or compression when carefully examined from the inside. There’s not much showing on the outside, but there are definite (albeit minor) constrictions internally. Both will be replaced (of which more in a moment).

- It was suggested that poor ammunition might be contributing to the problem, and that Lake City ball (i.e. the standard US armed forces round) would be a good ‘control’ to check this. I duly sent out some of my supply of LC M855 (NATO SS109) 62gr. ball for testing purposes, and feedback was immediately positive. It seemed to feed and function in most ‘problem’ weapons, with very few issues except in the two suspect upper receivers mentioned above. I’ve therefore asked those involved to check their existing ammo stocks, and consider spending a bit more for higher-quality stuff.

I’ve been looking into replacing the upper receivers of two carbines that showed problems (described in point 2 above). In order to make things more affordable for my students, I may end up giving one of them one of my 16″-barreled uppers , and replacing it with a 20″ (i.e. rifle-length) upper. That would give me a civilian AR15 equivalent to the US Marines’ current M16A4 issue rifle.

It’s long been a pet bugbear of mine how many people go with a 16″ or 14½” barrel on their AR15 uppers. I don’t think they realize how much bullet performance they give up in exchange for the shorter, handier weapon. Remember, the M4 (the military short-barreled version of the M16) was designed for use in armored vehicles and confined spaces, where the 20″ barrel and fixed stock of the standard M16 proved less handy. Most of us in the civilian world are not going to use our AR15’s from inside motor vehicles or in confined-space house-clearing exercises – or, if we are, we’d better have a whole lot more training than the average civilian AR15 owner!

The M16 was originally designed around its cartridge, and the modifications both have undergone since then have not always been beneficial to performance. Let’s recap briefly:

- The original M16 and M16A1 rifles had 20″ barrels with a 1:12″ rifling twist and fired a 55gr. projectile, known as the M193, at very high velocities. The bullet tumbled and fragmented upon impact, producing vicious wounding effects that made up for its small caliber.

- The M16A2 went to a 1:7″ rifling twist in its 20″ barrel to stabilize a heavier 62gr. projectile. Its new ammunition was known in the US armed forces as the M855 and in NATO as the SS109. It was designed to penetrate hard cover better than the earlier M193. It succeeded in this objective, but at the cost of much lower tumbling and fragmentation effects upon impact – instead it poked a neat (and very small) hole through the target, producing much less trauma. As a result it’s been widely criticized for being less effective against human targets than the earlier M193 round, particularly when fired out of the 20% shorter barrel of an M4 carbine. (The latter has largely replaced rifle-length M16’s in much of the US armed forces, except for the US Marines, who’ve stayed with the longer M16A4. The USMC has always held, preached and practiced the creed of “every Marine is a rifleman” – for which, God bless ’em!)

- Subsequent ammo developments have produced the M855A1 (which initially exhibited serious problems), Mk 262 Mod 1 (designed for longer-range shooting) and most recently the Mk 318 Mod 0 rounds, all of which were intended to address the M855’s shortcomings. The Mk 318 appears (based on initial reports) to be performing very well out of shorter barrels, but the USMC is apparently still issuing M855 ball for use in its M16A4 rifles.

All types of ammunition since the M193 (with the recent exception of the Mk 318) were initially designed to function out of the 20″ barrel of an M16 rifle with a 1:7″ rifling twist. Their performance out of the 16″ barrel of an M4 carbine was reduced, as they did not have sufficient barrel length to develop the full velocity for which they were designed. Furthermore, most civilian AR15’s have a 1:9″ twist, adequate but not optimum for best performance with the military rounds. When expanding (i.e. soft-point or hollow-point) ammunition is used this is much less of a problem, of course: but velocity is still down compared to a full-length barrel, which can make a difference at longer ranges.

Based on my own experience in military service, I’ve long been biased towards wringing the maximum possible performance out of the ammunition available to me. I’ve therefore been considering for some time upgrading my ‘defensive’ AR15 to something closer to the US Marines’ M16A4 rifle, including its 20″ barrel. It occurred to me that my investigation into carbine problems, and the need to help a couple of students replace sub-quality uppers, would be an excellent time to pursue this. I accordingly started shopping around, with my emphasis being the best military-specification upper receiver available to me with a 20″ barrel and high-quality components.

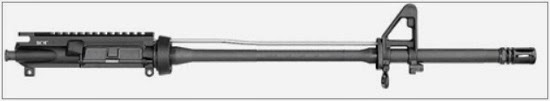

Many very positive reviews, including some cited by readers in comments to my earlier request for help, led me to Bravo Company. They appear to be one of the top AR15 manufacturers in the country, with a stellar reputation for quality and standing behind their products. Best of all, they have a milspec 20″ upper receiver currently on sale at what seems like a very reasonable price. It comes without handguards, but with their bolt carrier group; you can select handguards and a charging handle when you order it, if you don’t have them already. User reviews are uniformly very positive.

Mine arrived today. First impressions are of excellent quality of components and assembly. I’m going to be putting handguards on it soon, with Oleg‘s help, then we’ll install it onto several different lower receivers and test it. If it shoots as well as it looks, I think I’ll have found my new defensive long gun of choice. My existing 16″ upper will go to one of the two students who most need one, and I’ll look around to see whether I can locate another good-quality upper (or a complete carbine, for that matter) at an affordable price for the other one. (If any readers are able to help with that, please contact me – my e-mail address is in my blog profile.)

Thanks again to everyone who offered advice. You guys rock!

Peter

your comments about the 5.56 round are mirror my own totally uninformed guesses- shorter barrel, less velocity, less wounding effect,heavier bullets for more penetration, more stabilization, less wounding effect, an ever tightening spiral.

Seems like Mr. Kalashnikov may have had the ideal solution to short range carbines some time ago…

one additional item – take a look at FrogLube. I have a broomhandle Mauser that was hard to keep running until I FrogLubed the heck out of it and let it dry in the sun. wiped it clear of the excess after an hour or so, put it together, and haven't had a jam since.

@Anonymous at 10:20 PM:

"Seems like Mr. Kalashnikov may have had the ideal solution to short range carbines some time ago…"

In one sense, yes, he did: the 7.62x39mm round (which was developed on the basis of combat experience against the German 7.92x33mm Kurz) was a very effective intermediate round. Kalashnikov critized the Soviet Union's move to a 5.45x39mm round as a response to the US 5.56x45mm cartridge – he felt the earlier round was entirely adequate, and didn't see the need for the smaller one.

On the other hand, the smaller cartridges offer the possibility of carrying far more cartridges for a given weight, and produce much lower recoil. Their wounding effect, with a properly-designed bullet, is still at a militarily acceptable level, although perhaps not so much for police or civilian use (which is why special rounds have been developed for police use, such as, for example, Federal's Tactical Bonded law enforcement load).

The other answer for civilian use is to use soft-point or hollow-point ammunition, which greatly improves terminal ballistics against unarmored targets. That's what I've done – I wrote about it last year. See:

http://bayourenaissanceman.blogspot.com/2013/05/the-most-expensive-case-of-ammo-ive.html

"Won't the excess lubrication dry on the internal parts and gum up the action, or leak out of the receiver if the weapon's stored in an upright position, or perhaps affect the ammunition?"

Good choice of lubricants will help with that. A lot of people swear by Slip 2000 EWL (http://www.slip2000.com/slip2000_ewl.php) or FrogLube. I personally use Mobil 1 5W30 EP (full synthetic PAO-based motor oil) and it also works great in my experience, and stays wet a long time. Unlike petroleum distillates, PAO based synthetic oils don't seem to turn to gum even over extended periods, and they may also be better at not attracting gunk (one of the additional benefits is that any gunk that does accumulate, whether powder residue or otherwise, is kept in a fluid state so it won't bind things up). If the gun is lubed wet and then stored upright, a little excess oil might drain into the buffer tube (no biggie, that needs lubrication anyway) but it will not flow upward into the chamber or affect the ammunition. I do oil the "teeth" of the bolt but I make sure to keep oil off the bolt face, and have had no issues. I don't oil the bottom of the bolt carrier, to prevent oil from getting in the magazine. It also makes cleaning the gun easier, since wet powder fouling wipes right off.

To "top off" the lubrication of an AR while at the range, you can squirt a drop or two of Slip 2000 or Mobil 1 into the gas vent holes in the right side of the bolt carrier that you see through the ejection port.

You should be happy with the Bravo Company products. My Frankengun build used their bolt carrier group and charging handle.

Gerry

Your student might want to take a look at Palmetto State Armory's "Freedom" line of uppers. I've been quite happy with my 16" mid-length, and they usually sell for $225ish sans bolt group. Swap the bolt group from the problem child and life is good. (It appears they're out of stock at the moment, but expect that to change daily.)

Alternatively, a stripped upper receiver is $40-60, and an hour of time at the bench would swap the parts over…

Re: twist rates

It was my impression that it was designed for 1:14 but upped to 1:12 to stabilize the tracer (longer) bullet. Similarly, the 62gr bullet wants about 1:9 twist but once again they overstabilized it with 1:7 for the tracer bullet.

One of the advantages of the 20" over the 16" or shorter, is less apparent muzzle blast. Not only is it closer to your ears, but painfully louder. Nearby observers will notice a difference, also. Without earpro, the 16" fired inside an enclosure, or under a vehicle, is stunning.

IIRC, the loss of accuracy at 400yds in Arctic winter conditions was the claimed justification for the Army's switch to that really dirty powder that caused the early problems in Vietnam. I think they also switched to a slightly faster twist rate at the same time.

The claim of being able to carry more ammo in 5.56 than a soldier would be able to in 7.62, is somewhat bogus. The fact that they have to shoot their opponents multiple times before they see any result is what makes our rifle/ammo combo a less than stellar battlefield weapon.

They end up shooting them more than three times minimum, and it is not uncommon to dump half a mag into them. This problem is the number one complaint, besides sensitivity to sand/dust. The military should switch to hollowpoints. Remember, the justification for civilian use of hollowpoint ammo is that you don't have to shoot a BG as many times as you would with ball ammo to get them to stop, so they tend to survive, and with much less permanent damage. Of course, that is handgun ammo, and that may not correlate the same with rifles.

Twist rates…

The original 1:14 for the AR-15 R601 did fine until winter weather, where the round wouldn't stabilize in the denser air. The ammunition used here is pre XM193…

1:12 cured the winter weather problem in the AR-15 R602 and M193 stems from testing done from here and culminates in the M16 (R604) and M16A1 (R603).

1:9 is actually the ideal twist for SS109 and M855 ammunition. The problem with 1:9 is with the L110 and M856 tracer ammunition in winter weather. M855 and M856 are very long for their mass and it's length not bullet weight that decides what twist is correct. 1:7 stabilizes the tracers in Norway in the winter and slightly overstabilizes ball. The reason the M16A2 got a 1:7 twist is because the US Army insisted on it. Essentially out of fear that some grunt would miss with a tracer that was pried from an M249 belt.

There's a vocal group of people who advocate that the 1:7 is ideal because it's issue and they always seem to skip the actual history.

1) AR's run wetter than pretty much every other gun. In my experience the ideal level of lubricant is 'not quite dripping' but close. Note this only applies to the inside of the action/ BCG.

As to the too much oil attracts dust theory. You might need to clean the weapon slightly more often than if it's dry but most soldiers clean their weapons about daily anyway and most civilians aren't rolling around in sand all the time with their rifles. A reasonable amount of carbon or dirt/ sand on an oily BCG is not a show stopper.

I used mil tec in Iraq, CLP in Afghanistan and whatever was cheap in Arizona. Kept my rifle well lubed in all 3 and never had issues.

To the best of my memory I've never seen a mechanically functional AR that was sufficiently lubed have significant issues. Conversely many a dry problematic AR has been fixed with a couple squirts of oil.

If the liquid nature of oil is a concern for you Frog Lube or other similar gelatinous type lubes might be worth looking into.

3) If budget ammo is having problems a control batch makes sense. I once had a rifle that didn't like steel cased stuff.

Bravo Company makes truly professional grade gear. My rifle http://www.totalsurvivalist.com/2013/07/range-report-burris-mtac-dialed-in.html is almost all BCM and is every bit the gun as the Colt's I have used at work.

My rifle is a 14.5in with IRC 1/7 twist. I am a lot more likely to be going in or out of a vehicle or structure than needing a bit of extra velocity in the 400m+ range. My general observation is that utilizing decent ammo such as M855 or HP stuff if you hit people in the right place M4's work just fine.

A 20" A4 style gun as an SDM appeals to me. That and an M4 would be a nice pair.